16th January 2019

Learning with Stephan Angst how not to be scared on the rope

A rope access worker often performs work on a suspended rope at exposed places. Access to the workplace is only possible with ropes. For that, he needs not only a helmet with a chin strap, a full-body harness and a suspension/anchorage system but also sound and explicit training. We hired Stephan Angst, a top specialist, for such training.

Stephan Angst is holder of a Level 2 Certificate from SHRV, the Swiss Work at Height and Rigging Association, and has successfully completed the SRHT height rescue training. He is also employed as a competent person for the inspection of personal fall protection equipment.

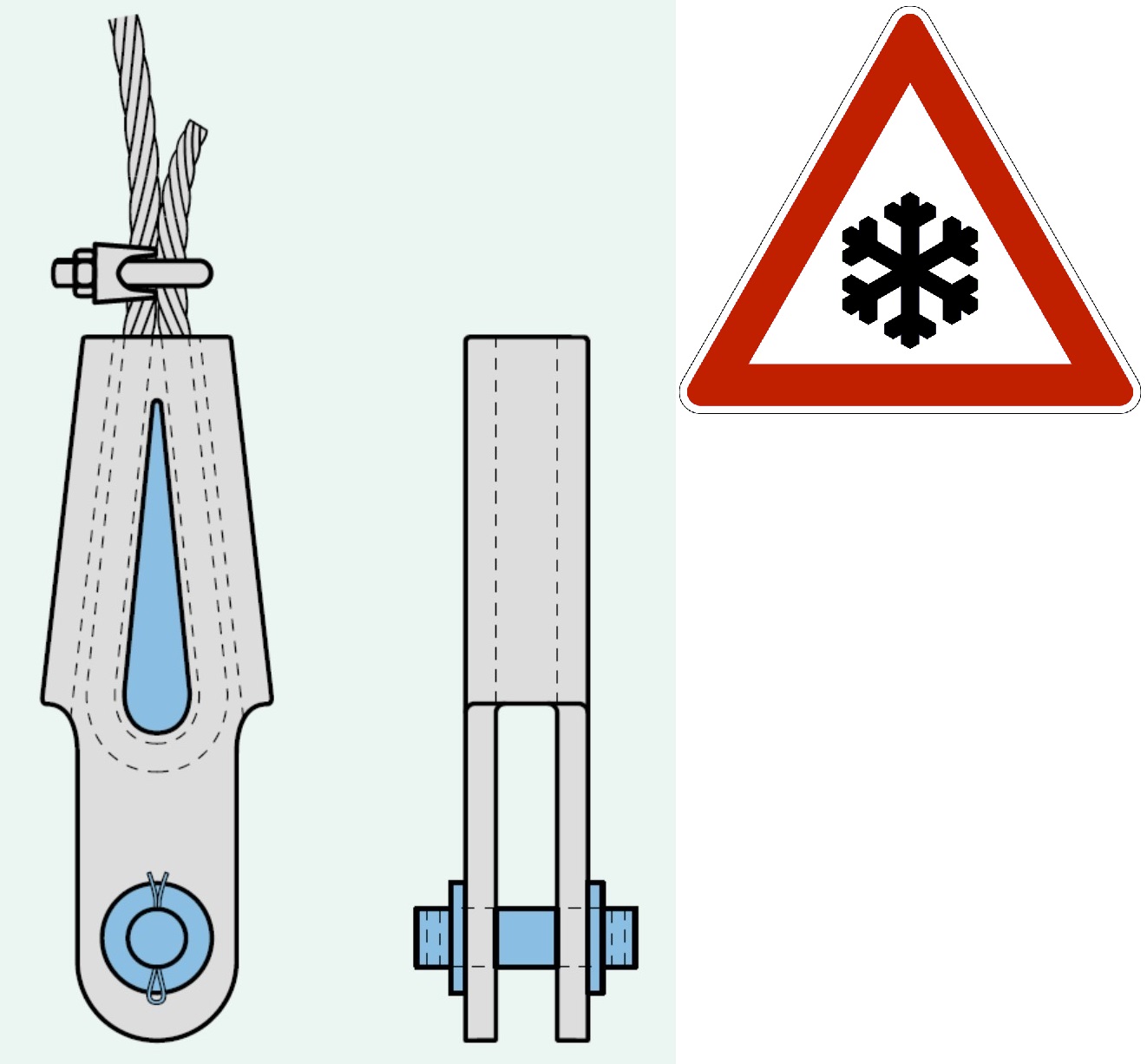

The HABEGGER company offers its customers a wide range of products from various manufacturers of personal fall protection equipment. Such equipment includes guided-type fall arresters, wedge anchors, full-body harnesses and work positioning belts, retractable-type fall arresters, lanyards, carabiners, helmets, descender devices, fall arrest devices, fall arrest nets, safety nets, double-legged lanyards and much more. An element of HABEGGER‘s complete personal fall protection equipment package is also the modular and individualised training of the customers on the equipment. The HABEGGER company provides tailored training and courses for that because the safety of the workers has top priority.

That is where Stephan Angst’s profound practical knowledge from his many years of experience comes in. He works on a multiproduct basis and trains the users on their own, sometimes already purchased, equipment. His pleasant way with people ensures a relaxed learning environment and even dispels potential and understandable fears of unpractised participants.

More details on the personal protection equipment topic can be found at the following link or in our H1 catalogue.

https://www.habegger-hit.ch/FB19/92-93/